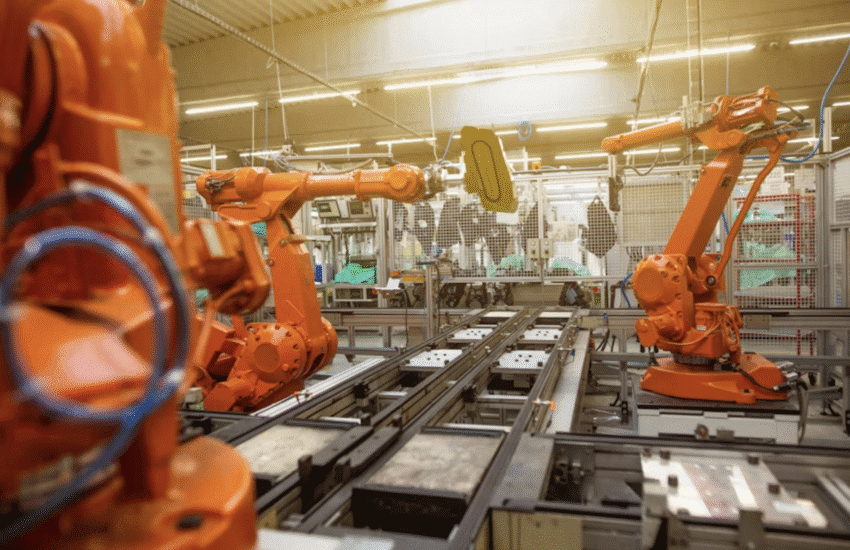

As the role of modern machinery within business grows by the year, the need to keep assets protected becomes greater too. Only a comprehensive strategy will suffice.

From manufacturing equipment to computer tech and vehicles, all business machinery needs attention. Focus on the five simple steps below to keep yours performing as they should with immediate and long-term success.

Protect Fragile Machinery Elements

Even the most robust machinery will feature potentially fragile parts. Sadly, if they become damaged, the entire machine may stop working. Using a polyurethane tube to protect wiring can prevent a power outage caused by damage to the wires inside. Meanwhile, some equipment may benefit from shields or casing around certain parts. As well as stopping a breakdown, it can stop minor problems that would compromise performance output.

Failure to do this could lead to significant downtime. When added to the costs associated with finding and fixing the problem, the impact on your business could be huge.

Maintain Safe Workspaces

In order to protect machinery, you must also consider the surroundings. The harsh reality is that a workplace disaster could result in irreparable damage, leaving you faced with an uphill battle. Knowing how to successfully prevent fire hazards and explosions in the workplace should be a priority. Similarly, keeping the workplace free from leaks and excessive dust will protect equipment as well as employees.

The layout of workspaces is also important. Giving machinery space for ventilation can help prevent overheating. As well as the damage it subsequently brings.

Invest In Machinery Maintenance

Of course, it’s important to invest in the right machinery and ensure that all assets are correctly installed. However, long-term performances are equally reliant on proactive maintenance. Monitoring all machinery with the OEE method is particularly useful. As soon as the early signs of an issue are identified, you can schedule the necessary maintenance. This prevents future unscheduled downtime and restores efficiency ASAP.

From simple steps like lubricating stiff parts to more advanced repairs, quick action makes all the difference.

Train Your Employees

Whether it’s a machine operator or an office computer user doesn’t matter. The actions of your employees will have a huge influence on the long-term health of your assets. Therefore, staff training on how to use equipment, hardware, and software is essential. Aside from protecting your assets, it is a great way to build consistency across the team. And it will show in the results generated over time.

On a side note, investing in this type of staff development can make employees more engaged. In turn, this boosts productivity while also slowing staff turnover.

Implement Digital Protection

Finally, a growing percentage of machinery is now online. Whether connected to an IoT network or linked to data tracking tools doesn’t matter. Any asset that is online could potentially come under attack from a cybercriminal. Therefore, building a robust cyber defense system vital for protecting machinery as well as sensitive data. It is an integral feature for any business that wishes to maintain smooth daily operations.

Once your business is suitably protected in both the online and offline arenas, you will be free to unleash the potential of your assets. Perfect.

- Avoiding the Recall Spiral: Why Equipment Design Demands Greater Focus

- The Foundation of Merger And Acquisitions Success: Strategy, Flexibility, and Precision

- For Manufacturers, Quality Control Should be a Sales MVP

- Investing in Retention: How Benefits Support a Stronger Workforce

- Cybersecurity Essentials for Customer-Facing Platforms: Safeguarding Trust in a Digital-FirstWorld